YOUR SPECIALIST FOR LASERS, EDITING, BENDING, STAINLESS STEEL PROCESSING AND SPECIAL MACHINE CONSTRUCTION.

Our company is a highly efficient operating manufacturing company, located in Thuringia - in the center of Germany. With our wide range of services we are your expert in laser cutting, bending and stainless steel processing from miniature to XL.

Since its establishment in 1996 as a subsidiary of Avermann Maschinenfabrik GmbH & Co. KG, Osnabrück, the company is characterized by a steady and healthy growth. Currently, there are more than 60 employees and 3 apprentices are trained in commercial and technical areas.

Based on our own demand for high quality, on the outstanding qualifications and continuous training of our employees, our company is now among the top 10 German subcontractors in the field of laser cutting. One proof of this is the certification according to standard DIN EN ISO 9001:2015 by the TÜV Thüringen e.V., first accomplished in 1996 according to the old DIN EN ISO 9001:2015.

Expansion of stainless steel competence at theAvermann Laser- und Kant-Zentrum in Amt Wachsenburg

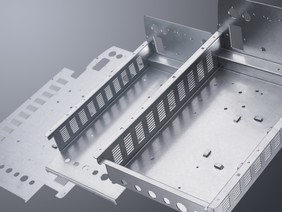

In the course of the further development of the company and especially for the expansion of the production of high-quality assemblies made of special materials, the possibilities for manufacturing of stainless steel assemblies are significantly expanded at the location in Amt Wachsenburg (Thuringia).

For the creation of the new stainless steel competence center, the production area specially provided for this area will be increased from currently around 800m² to over 1400m²! This goes hand in hand with the creation and restructuring of all storage and production areas for completely corrosion-free production.

In addition to the development and expansion of capacities, qualifications and certifications that are currently available for TIG welding of high-quality stainless steel assemblies, extensive investments are being made also in quality-assurance and machine-equipment.

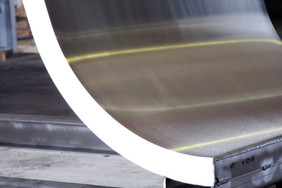

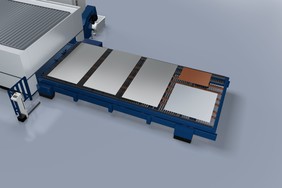

A new TruLaser 3060 fiber (10kW) laser from Trumpf was ordered at the end of August 2020. These additional laser with the newest fiber technology will almost double the cutting capacities for stainless steel products at the site.

In addition, the investment in a new TruBend 5320 bending-machine with Toolmaster from Trumpf is in preparation for 2021. By configuration of the machine, we will significantly optimize our technical options and productivity for all bending-processes.

In the future, we will be able to offer our customers a comprehensive range of services from small and large-format laser- and bending-parts to the complete production of large stainless steel assemblies.

With the decision to expand the stainless steel competence center and the extensive investments, we are creating the basis for a value and sustainable expansion of the company and thus securing the future viability of our location in Amt Wachsenburg.